The artificial intelligence revolution in the manufacturing industry

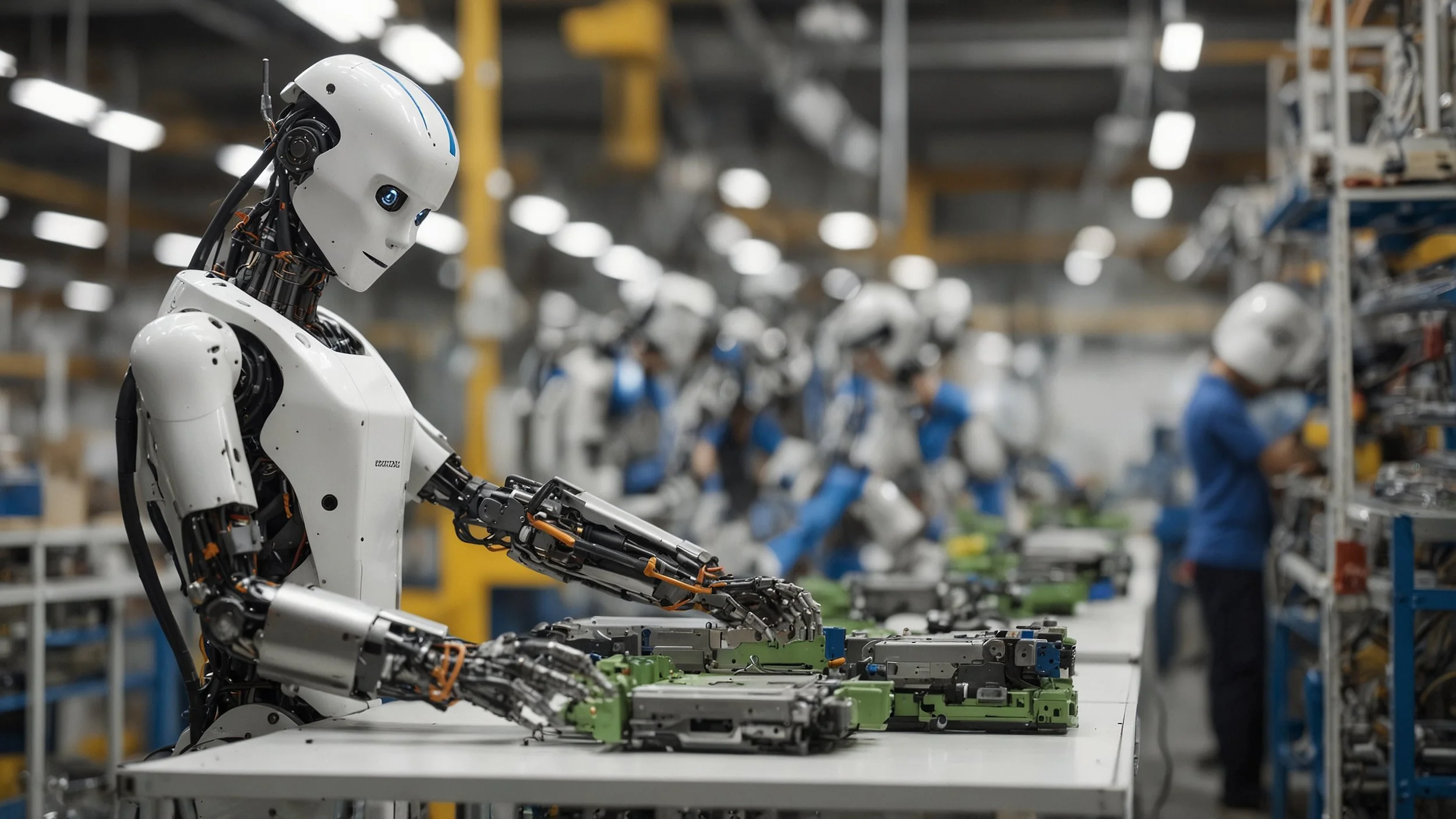

Automation powered by artificial intelligence is no longer a futuristic concept but a tangible reality that is transforming the manufacturing industry. Sectors as diverse as cosmetics, food and electronics are adopting technological solutions that optimize processes, raise standards and significantly reduce costs. This integration not only redefines the way we produce, but also offers crucial competitive advantages in an increasingly demanding global marketplace.

Boosting productivity and quality with AI and robotics

In several factories specializing in everyday products, the application of artificial intelligence and robotics has driven remarkable progress in productivity and quality. For example, a contact lens manufacturer implemented AI systems to anticipate failures in its machines, thus maximizing production. In parallel, a cosmetics company was able to automate almost its entire production line, significantly reducing unit costs and improving overall process efficiency.

Optimization of the supply chain with intelligent agents

Efficiency in the supply chain has seen significant progress thanks to the incorporation of intelligent agents that automate key processes, such as order fulfillment and logistics optimization. These systems not only speed up operations, but also ensure greater accuracy and error reduction, improving overall supply chain management.

In plants specialized in battery manufacturing, intelligent visual systems are used to perform a continuous inspection of product quality, detecting anomalies in real time.

These systems are able to predict potential defects before they evolve into major problems, minimizing unexpected downtime and costs associated with failures.

The implementation of this technology promotes continuous improvement in production processes, ensuring high standards and optimizing resources.

It also frees workers from repetitive and prospective tasks, allowing human talent to focus on activities with greater strategic and creative value, enhancing innovation and competitiveness.

Industrial transformation and competitive advantages

The examples described above demonstrate how artificial intelligence (AI) is revolutionizing the manufacturing industry by offering substantial benefits in various operational aspects. This technology not only optimizes costs, but also improves the accuracy and speed of processes, while increasing safety in the work environment.

AI can generate significant cost reductions by automating repetitive tasks and optimizing the use of resources, thereby reducing waste and improving energy efficiency.

Thanks to advanced algorithms, greater production accuracy is achieved, minimizing human error and guaranteeing superior quality standards in the final products.

The speed of industrial processes is significantly accelerated, allowing rapid adaptation to changing market demands and shortening production cycles.

In terms of operational safety, AI implements predictive monitoring systems that identify risks and prevent accidents, protecting both workers and facilities.

Finally, the strategic and thoughtful implementation of AI technology enables manufacturing companies to transform their operations, maintaining a strong and sustainable competitive advantage in an increasingly dynamic industrial environment.

Automation with artificial intelligence is already a tangible reality that drives productivity and quality in contemporary manufacturing. For companies seeking efficiency and scalability, these advances confirm that investing in intelligent technologies is not only a step into the future, but an essential strategic decision to lead in a competitive and dynamic environment. Adapting to this technological evolution is crucial to ensure solid and sustainable growth.